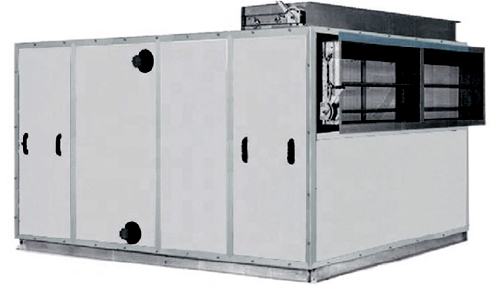

Air Handling Units

PureQuest Air Handlers are designed and manufactured in South Africa by a Team of dedicated professionals through adopting the latest HVAC & R technologies with the aim of expediting manufacturing, easing project constructability, and streamlining maintenance. Our strategy is centered on exploiting every opportunity for cost reduction and as such we pass the realized cost savings to our valued Customers. This is achieved through capitalizing on a cost-efficient supply chain, shortening delivery lead times and cultivating quality from cradle to market to avoid defects. PureQuest air handling units are built for superior air quality distribution from the most rudimentary design right up to the more sophisticated offerings required for high specification environments such as clean rooms, laboratories, pharmaceuticals, food & beverage Industries. Our standard models range from 500L/s to 30,000L/s are, larger sizes can be customized to fit requirements. Some units are modular in construction and the construction methodology is current to the global best practices

AIR FILTRATION

Our Filters range from panel type coarse filters, bag, cartridge, carbon, high efficiency particulate and ultra-low particulate air filters. The filter frames are offered in galvanized iron, aluminium, stainless steel, and plastic frames depending on the application. Mixing boxes and filter sections can be custom made to conform to project specific requirements. Panel, bag, and rigid filters are constructed for front withdrawal as a standard and side withdrawal as an option

FRAME CONSTRUCTION

PureQuest air handlers are constructed from a sound design of the framework and panels which ensure structural integrity, robust strength, and stability. Frame material selection accounts for risks posed by the operating environment. The standard offerings are stainless steel and galvanized iron. Corrosion resistant extruded aluminium pentapost section rigidly joined by die – cast monobloc corners is offered as an option.

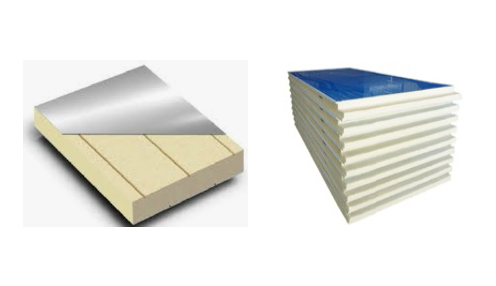

HOUSING PANELS

Double skin insulated panels come as a standard, this enhances insulation efficiencies, increases longevity, curtails air leakage, reduces air fugitive infiltration, and provides superior acoustic performance and noise breakout containment, resulting in less noisy units. Alternative panel options marine grade aluminium, galvanized iron, or stainless steel. Special finishes such as powder coating or epoxy painting are available upon request. There are numerous insulation options depending on the acoustic and heat transfer requirements. Insulation thickness is nominal 50mm as standard, with nominal 25mm, 40mm and 60mm options. All panels are fixed with screws, or external clamps and quick release fasteners. Access doors are double skinned with positive seal latches and can be opened from inside the unit.

Door hinges and a selection of locking devices is available and optional accessories such as inspection portholes and bulkhead lights are also available as options.

Door hinges and a selection of locking devices is available and optional accessories such as inspection portholes and bulkhead lights are also available as options.

AIR TREATMENT SECTION

Heat and Cooling Coil selections are made up to 12 row coils of depth and fin spacing that provides optimization depending on the application. Standard construction is aluminium fin and copper tubes with galvanized end plates and post-manufacture acrylic anti-corrosion treatment for the whole coil block. Customized surface treatments, fin and tubing materials are available on request. All cooling coils are sized to a suitable aspect ratio, face area and velocity to minimize moisture carryover and condensate loading.

Drain trays are manufactured from stainless steel as standard, to mitigate corrosion, free draining and easy to clean without removing from the unit. Trays are supplied with a flexible outlet connection and drain pans are externally insulated with polyethylene foam with foil faced vapor barrier to prevent condensation forming on the exterior.

Drain trays are manufactured from stainless steel as standard, to mitigate corrosion, free draining and easy to clean without removing from the unit. Trays are supplied with a flexible outlet connection and drain pans are externally insulated with polyethylene foam with foil faced vapor barrier to prevent condensation forming on the exterior.

FAN SECTION

Fans are available in forward curved, backward curved or aerofoil bladed as required and housed or unhoused plenum (plug fan) variants, with both belt and direct driven options.

As a standard, all fans are mounted on anti-vibration mounts with a flexible connection to the unit casing. Holding down bolts are provided for shipping purposes.

As a standard, all fans are mounted on anti-vibration mounts with a flexible connection to the unit casing. Holding down bolts are provided for shipping purposes.

OPTIONS

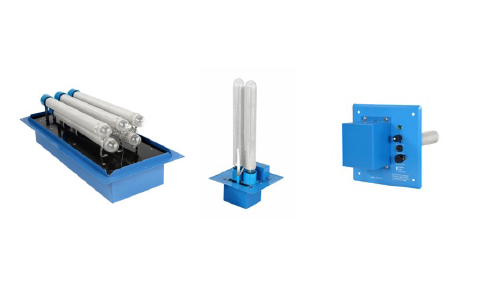

Bi-Polar Ionisation is a cutting-edge sterilization and odour elimination technology. The principle of ionization purification system works by passing the supply airstream along an ionization tube, where airborne particles are charged to form positive and negative ions. When the supply air is circulating through an occupied room, those ions are attracted to air pollutants. The process damages the cell structure of virus, mold spores as well as bacteria which are deactivated shortly after contact with the ions, thereby eliminating the microorganisms to prevent the spread of diseases and odors. As an option, the ionization tubes can be installed at the supply air outlets of AHUs, FCUs and Ducts. Ionization tubes are easy to install, have high sterilization efficiency and have great acoustic performance.

| MODEL | AIR FLOW M3/S | AIR FLOW CFM | AIR FLOW M3/H | COOLING CAPACITY (TONS) |

|---|---|---|---|---|

| QOOL-05 | 0.5 | 1,059 | 1800 | 2.4 |

| QOOL-10 | 1 | 2,119 | 3600 | 4.7 |

| QOOL-20 | 2 | 4,238 | 3601 | 9.4 |

| QOOL-30 | 3 | 6,357 | 3602 | 14.1 |

| QOOL-40 | 4 | 8,476 | 3603 | 18.8 |

| QOOL-50 | 5 | 10,594 | 3604 | 23.5 |

| QOOL-60 | 6 | 12,713 | 3605 | 28.3 |

| QOOL-70 | 7 | 14,832 | 3606 | 33 |

| QOOL-80 | 8 | 16,951 | 3607 | 37.7 |

| QOOL-90 | 9 | 19,070 | 3608 | 42.4 |

| QOOL-100 | 10 | 21,189 | 3609 | 47.1 |

| QOOL-110 | 11 | 23,308 | 3610 | 51.8 |

| QOOL-120 | 12 | 25,427 | 3611 | 56.5 |

| QOOL-130 | 13 | 27,545 | 3612 | 61.2 |

| QOOL-140 | 14 | 29,664 | 3613 | 65.9 |

| QOOL-150 | 15 | 31,783 | 3614 | 70.6 |

| QOOL-160 | 16 | 33,902 | 3615 | 75.3 |

| QOOL-170 | 17 | 36,021 | 3616 | 80 |

| QOOL-180 | 18 | 38,140 | 3617 | 84.8 |

| QOOL-190 | 19 | 40,259 | 3618 | 89.5 |

| QOOL-200 | 20 | 42,378 | 3619 | 94.2 |

| QOOL-210 | 21 | 44,496 | 3620 | 98.9 |

| QOOL-220 | 22 | 46,615 | 3621 | 103.6 |

| QOOL-230 | 23 | 48,734 | 3622 | 108.3 |

| QOOL-240 | 24 | 50,853 | 3623 | 113 |

| QOOL-250 | 25 | 52,972 | 3624 | 117.7 |

| QOOL-260 | 26 | 55,091 | 3625 | 122.4 |

| QOOL-270 | 27 | 57,210 | 3626 | 127.1 |

| QOOL-280 | 28 | 59,329 | 3627 | 131.8 |

| QOOL-290 | 29 | 61,448 | 3628 | 136.6 |

| QOOL-300 | 30 | 63,566 | 3629 | 141.3 |